After more than ten years of technological accumulation, we have established an independent provincial-level research and development center, our own industrial park, and have been awarded titles such as provincial-level specialized, refined, innovative, and technological enterprise. These honors witness our strength and our strength creates brilliance.

We will extend our professional leverage infinitely, deeply cultivate and refine in the field of industrial kiln products and process production line construction, embed wisdom into every corner of manufacturing technology, highly integrate cutting-edge research and development technology with the trend of the times, subvert industry traditions with world-class equipment and high-precision end processes, and obtain multiple high standard certifications and national patent certificates.

Carefully selected, with meticulous polishing and continuous carving, thousands of processes, craftsmanship and quality poured into every inch, creating a prosperous era of equipment.

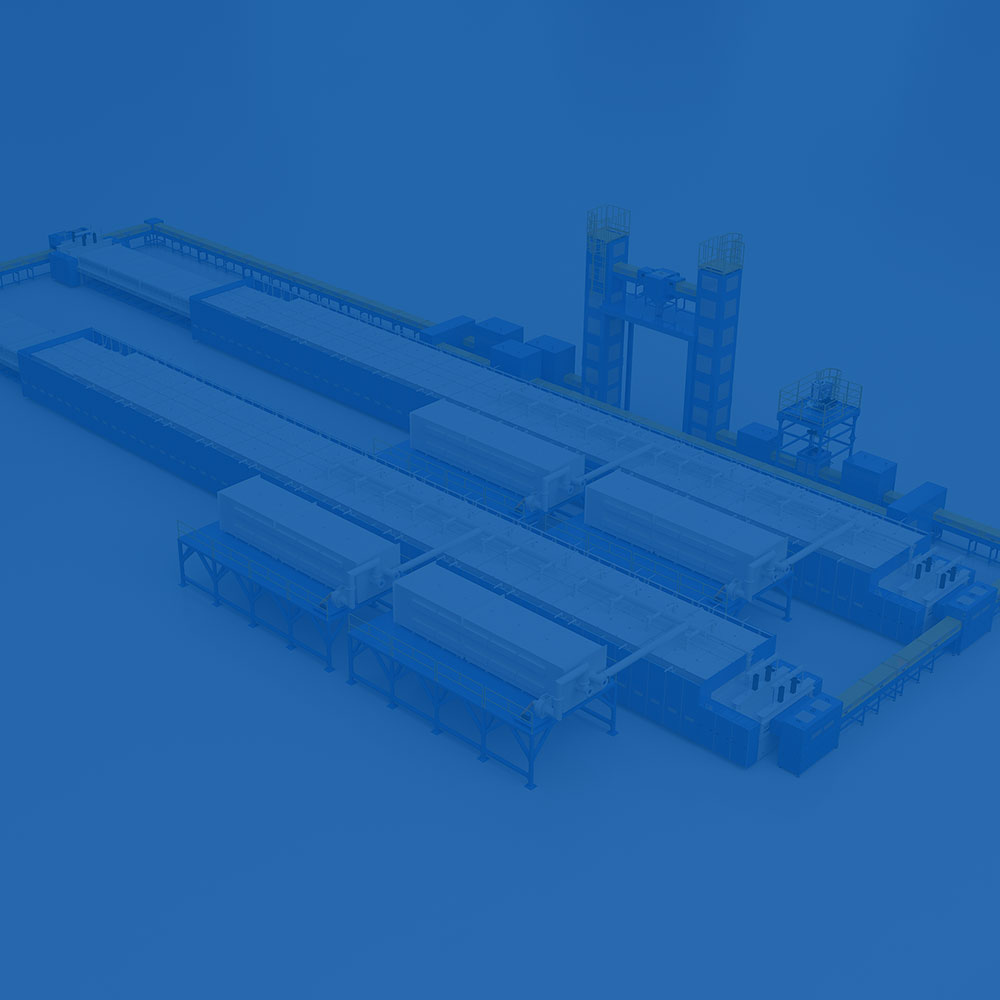

Honghai Equipment, with over ten years of craftsmanship and market-oriented development, has developed the following main products:

Every exploration is a breakthrough, every innovation is a leap forward, focusing on equipment applicability and maintainability, emphasizing high-precision fitting between equipment and product processes, and achieving full process control; Unique thermal structure and atmosphere design, saving 20-25% energy compared to the same period last year; The ancient mortise and tenon structure masonry is resistant to high temperatures, oxidation, and acid and alkali erosion;

Our products are widely used in industries such as new energy (lithium-ion/sodium battery positive and negative electrode materials), new materials, electronic materials and devices, ceramic materials and devices, semiconductor materials, automotive electronics, chemical engineering, magnetic materials, biopharmaceuticals, etc.

Based in Xuancheng and looking to the world, we are exporting HONGHAI kiln equipment to the world. We work together, strategize, assess the situation, and take advantage of the situation to achieve intelligent manufacturing, digital operation, and green industry with advanced planning that leads the entire industry. We aim to achieve HONGHAI's speed in the fields of new energy, new materials, and electronic devices.

From intelligent design to one-stop after-sales service, we strive to create a professional and efficient after-sales service guarantee for the entire lifecycle of equipment.

With a professional team background of 20 years in the research institute, we have integrated the special and new technology strength of Germany, Japan and other countries, benchmarked against the cutting-edge equipment technology of many countries. New technologies, new formats, high efficiency and intelligence have emerged, realizing full automation and intelligence of production, and continuously injecting new momentum into the digitization of equipment.

Taking advantage of the situation and embarking on a new journey to build a strong intelligent manufacturing industry, HONGHAI defines industry standards with high requirements and creates a business blueprint with sincerity, committed to building a world-class supplier and service provider of heat treatment and automation equipment systems!

The founder and technical and service team of the company have over 20 years of experience in professional technical research and design in research institutes and foreign-funded enterprise groups. They have rich experience in equipment production, maintenance, and customer frontline use, as well as the ability to solve problems.

The company has established close cooperative relationships with professional technical experts from countries such as the United States, Germany, Japan, and Canada, providing us with cutting-edge technology research and technical support.

Focus on device applicability and maintainability;

Pay attention to high-precision fitting of equipment and product processes;

Realize stable temperature and atmosphere fields;

Realize high-precision process control.

Independent development and modular design;

Refractory materials inside the mold forming furnace;

Ancient mortise and tenon structure masonry;

Strong durability and easy maintenance;

High temperature resistance, oxidation resistance, acid and alkali resistance.

Unique thermal structure and atmosphere design;

Excellent material selection and matching;

Efficient and energy-saving, Energy savings of 20-25% year-on-year.

Unique code certificate, database management;

Artificial intelligence and remote assisted regulation,

Significantly improve stability and reliability;

Realize intelligent operation and remote maintenance.